Our products

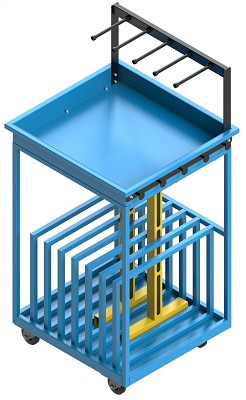

MOBILE WORKSHOP TROLLEY

Better workshop organisation & essential tools always at hand

Proper organisation of mould service workstations is the key to efficient and comfortable working, which translates into workshop efficiency and productivity. It is very important that service technicians always have the most important tools and utensils at hand, but it often happens that they are scattered between different workstations. With limited workshop space, storage of these items also becomes a problem, and the lack of organisation translates into a longer service process.

In response to the needs of all mould workshops striving for maximum comfort and productivity, we have designed a mobile workshop trolley specifically for mould service workstations. Thanks to this trolley, service technicians will no longer have to worry about tidiness and organisation at the workstation, and the fully mobile trolley will not permanently occupy valuable workshop space, but will enable it to be taken anywhere in the plant, depending on the current needs.

FEATURES AND FUNCTIONALITY

-

Our workshop trolley has been carefully designed to meet both the highest utility and durability requirements. Robust workmanship guarantees high strength and a long service life.

-

Large and sturdy wheels make it possible to transport it anywhere in the workshop. Not only does the trolley not permanently occupy valuable workshop space (it can be moved to any location), but it ensures that all the most important items are always at hand - even when mould work has to be carried out outside the workshop.

-

The storage space on the trolley can be used as desired - allowing tools and sprays to be stored or using separate containers to store many smaller items.

-

Numerous hooks will allow for the storage of items such as slings or eye bolts, necessary for mould handling.

-

The trolley has brackets to put down the steel angles with bean holes we supply.

Along with our trolley, we can supply a set of T-shaped steel angle brackets. Their role is to hold the mould-plates firmly in an upright position, which significantly increases work safety and minimises the risk of injury to the service technician and damage to the tool. The plates can be fixed using eg. screws from the side, and the bean holes guarantee a vast adjustment range.

YOUR ADVANTAGES

-

Robust, sturdy and carefully crafted design

-

Fully mobile with optimal dimensions

-

The most important equipment & tools are always close at hand

-

Better workshop organisation = increased productivity

-

Versatile storage space for any arrangement

-

Numerous hooks for eye bolts or slings for mould service

-

Compartments for storing angle brackets or plates

-

Angle plates significantly increase safety when working on moulds at a very low investment cost.

-

The ideal supplement for our workbenches and mould service tables